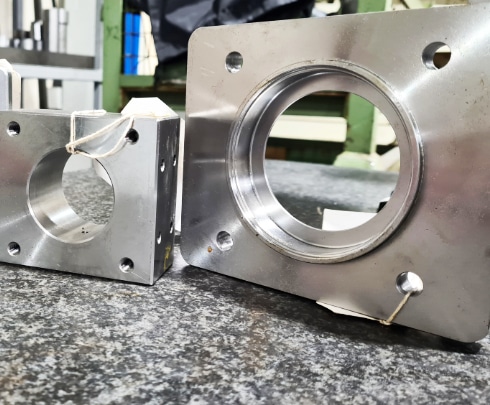

Bellcliffe Engineering can create the following rolling mill components, either using your own designs, or by utilising our own design capabilities, to complement your machinery perfectly:

Capabilities & Technical Specifications

Supported by over 100 years of combined experience in this field, Bellcliffe Engineering can provide proven solutions for your roll forming problems, without compromising on the quality of the product. Starting with a free site survey, we work in conjunction with your existing machinery and components, to ensure the parts we provide are complementary to your processes. Bellcliffe Engineering can work with a range of materials, depending on your specifications and tube thickness and diameter. And, best of all, we do this globally.

All of our components are manufactured around your specifications; get in touch with Bellcliffe Engineering to discuss technical specifications further.

Applications

Bellcliffe Engineering provide roll forming tooling and mill components for all sectors, including, but not limited to:

Got A Question? Get In Touch

FAQs

In a rolling mill, the shaft serves as a central axle from which torque and rotation from the gearbox is applied to the rolls; this is aided by driven shafts and spindles, which are connected to the rolls to facilitate the rotation required. Shafts and spindles are supported by the stands, running the length of the rolling mill line.

Cutters or shear blades are teeth elements that shear material into parts through a cutting process. Similarly, cut off dies are used to cut material at a precise length, leaving excess metal in an untrimmed strip on the end of the blank, whilst circular knives rotate on their own axis and swing in a circle to cut.

Excess material is removed by slitter and separator blades; separators are used to isolate the layers of the material web to avoid sheet stock contamination.

Spacers serve as connections between other mill components such as bearings and the frame.

Bearing sleeves provide clearance in a machine spindle for linear or rotational movement.