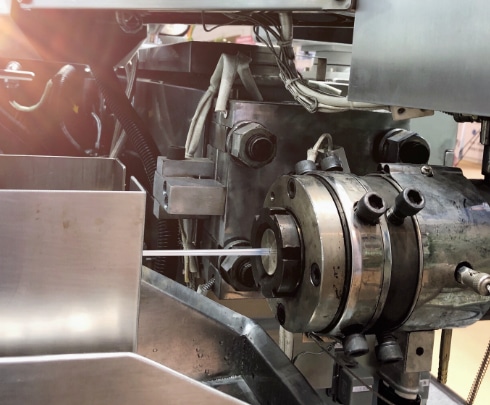

Continuous rotary extrusion, otherwise known as CRE, is a manufacturing method in which the material to be formed, known as the feedstock, is continuously guided by a coining roll onto the circumference of an extrusion wheel. The feedstock is bent around the wheel before being blocked by a fixed abutment. This creates great pressure and heat, which makes the feedstock malleable; the now malleable metal is fed through a die, forcing the metal into a desired shape or profile. Continuous rotary extrusion is a common method for creating seamless tubes, as the extrusion process forms a continuous, rather than discrete, shape, which eliminates the need for additional fabrication processes such as welding.

Bellcliffe Engineering provides a multitude of high quality parts to aid the extrusion process; we have experience designing and manufacturing consumable parts, such as extrusion wheels and abutments, as well as head frame assemblies and extrusion shoes. Bellcliffe Engineering works to ensure your continuous rotary extrusion operation lines run as efficiently as possible through providing precision and reliable components.

Capabilities & Technical Specifications

Bellcliffe Engineering have over 100 combined years of experience within this field, providing trusty solutions for all types of manufacturing machinery problems. We maintain an open line of communication with our customers to ensure their products are suitable for their application; as a part of this, whilst working with Bellcliffe Engineering, you can select the right materials and heat treatments for your unique applications.

We meet Industry Standards whilst manufacturing components for your safety and peace of mind.

Our extrusion tooling is made to measure, and the material selection is determined by your operational variables. For exact technical specifications for your components, talk to a member of our team today.

Applications

Many sectors use continuous rotary extrusion, and Bellcliffe Engineering can cater to all

Got A Question? Get In Touch

FAQs

Continuous rotary extrusion is supported by many components. Some of these main components consist of: a coining roll and wheel, which guide the feedstock; an abutment, feedplate, and die, which respectively help stop and guide the metal into the die where it is moulded; the abutment, die, and feedplate are all kept within the shoe.

Of course, the tooling used is dependent on the type of extrusion process. For instance, direct, or forward, extrusion must use a ram to force the feedstock into a die. Continuous rotary extrusion, on the other hand, works on the principle of friction to help drag the feedstock onto the wheel.