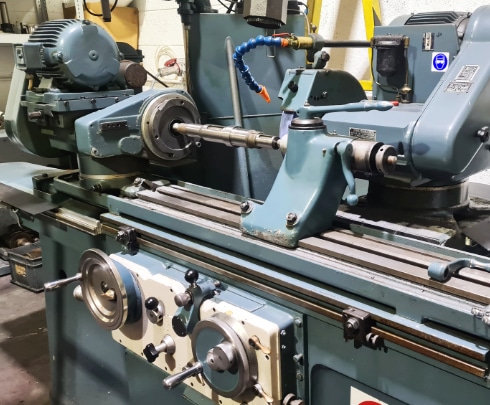

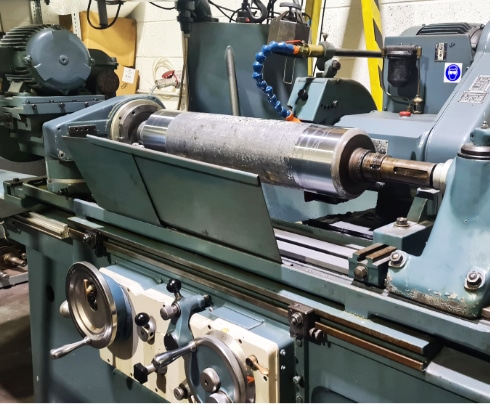

Cylindrical grinding differs from surface grinding since it works by rotating the workpiece alongside the spinning grinding wheel. This allows for symmetrical grinding on cylindrical shapes which have a central axis of rotation. The grinding wheel subsequently moves towards and away from the workpiece, or along it with the use of a fixed bed. Like surface grinders, cylindrical grinders can be applied to a variety of materials, including numerous metals and plastics.

With our cylindrical grinding capabilities, Bellcliffe Engineering can provide you with a superior finish to your products, ensuring they meet all your requirements, without compromising on quality.

Capabilities & Technical Specifications

Applications

Our cylindrical grinding services can be used for a number of sectors, including...

FAQs

Cylindrical grinding provides a finishing operation by improving the quality of surfaces through the careful removal of excess material. This is an important step in the finishing process of a workpiece, guaranteeing the product is of the desired shape and size.

Cylindrical grinding in particular is used for grinding cylindrical shapes, such as pipes and tubes.