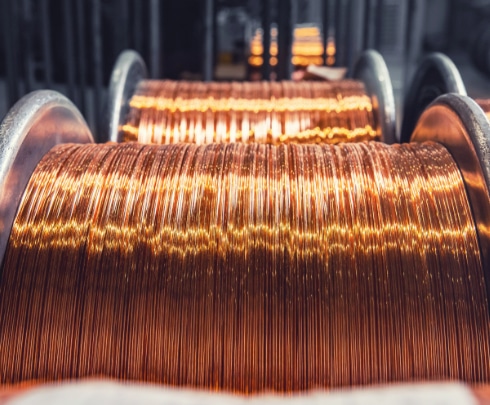

There is a rising demand for copper, with the value of the metal continuing to increase. Maintaining the quality of your copper products, therefore, is a high priority for many manufacturers - and this often starts with the handling of the product during rolling.

Copper rods are a product of copper sheets first being melted down and formed into a billet through continuous casting, before being rolled through a machine until they take on a round section; the forming of copper rods is undertaken on continuous casting rolling lines for this reason.

The rolls used within the production of your copper rods are essential to the quality of the product. This includes both the quality of the steel rolls used, and the correct application of heat treatment. Bellcliffe Engineering manufactures copper rod rolls with the elevation of your product in mind.

Capabilities & Technical Specifications

Bellcliffe Engineering provides a free site survey to determine your requirements, we then work with a variety of materials to best match your specifications. With over 100 combined years of experience behind us, manufacturing worldwide, Bellcliffe does not compromise on quality whilst delivering to even your most complex needs. We provide bespoke solutions to all your roll forming problems, in order to refine and renovate your production.

We design our machinery and components to your exact specifications. Curious about how we can design around your business? Get in touch to find out today.

Applications

Bellcliffe Engineering provides made to measure components and machinery to fulfil the needs of a variety of sectors, including:

Got A Question? Get In Touch

FAQs

With the ability to conduct electricity, and additional corrosive resistance, copper is used throughout a variety of industries.

One of the most important uses of copper is in electrical wiring. Large cables are used to bring power from plants to where it is needed by consumers, whilst finer wiring within buildings makes this energy accessible all around. Alongside wiring, copper is often used in motors for the same principles.

Another industry that takes advantage of copper is the construction industry.

Copper is often used in plumbing, for pipes and tubing, since it is resistant to corrosion. In the same vein, copper is a popular choice for reinforcing or covering metal framework in building applications, due to its ability to absorb vibrations, and remain resistant to corrosive conditions.