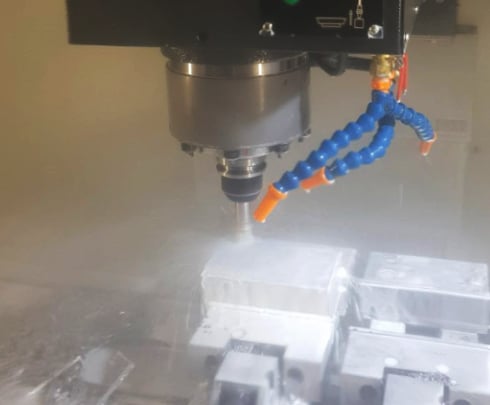

Machining can be an automatic or manual process; however, automatic machining is becoming increasingly common today due to its elevated capabilities, accuracy, and precision, by means of CNC (Computer Numerical Control). CNC machining is used by a plethora of industries - from automotive and aerospace, to the medical industry and oil and gas.

Bellcliffe Engineering have invested in industry-leading equipment to be able to offer professional machining services, operated by competent machinists:

Capabilities & Technical Specifications

Bellcliffe Engineering works closely with our customers to ensure their needs are met; we use a Hexagon Absolute Arm whilst machining, so that calibration is both accurate and speedy. Our absolute arm is accurate to within ± 9 Microns. We moreover work with a range of materials, and use CAD and CAM software when designing your workpieces, to meet your specifications with precision.

Bellcliffe Engineering has over 100 years combined experience, and have delivered our services globally - you can trust us to find solutions to all your machining problems.

Bellcliffe Engineering offers CNC Turning with our 2016 Doosan 3100L 2 axis lathe, and 2x Nakamura ST4 2-axis lathes.

For grinding, Bellcliffe Engineering uses a Chevalier Surface Grinder, and a Jones & Shipman Universal Grinder.

Our wire erosion services are completed by way of our 330F Robofill Wire Eroder.

Applications

Bellcliffe Engineering can provide machining services for a number of sectors, including, but not limited to, the following:

Got A Question? Get In Touch

FAQs

CNC is an abbreviation for Computer Numerical Control. Therefore, CNC machining processes and actions are controlled by pre-programmed computer software.

CNC machines are accurate and fast, can handle high volume operations, with a high aptitude for repeatability. They require less skill for operation, and can reduce workplace hazards, as opposed to manually machining. However, they are more expensive to purchase.