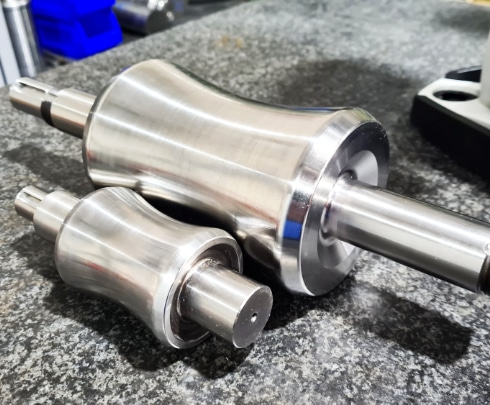

Bellcliffe Engineering creates straightening rolls for this purpose, helping you achieve perfectly straight tubes every single time. Our expertise, supported by decades of experience, means we can design straightening rolls to fit your specific requirements and needs.

We understand the great strain your straightening rolls are placed under, and so Bellcliffe Engineering prioritises durability and precision when designing and manufacturing straightening rolls.

Capabilities & Technical Specifications

At Bellcliffe Engineering, we have over 100 years of combined experience guiding us, allowing us to provide leading solutions for all your tube rolling problems. Following a free site survey, we will continue to work in close partnership with you to ensure your machinery and component products meet your exact specifications. We can work with a range of materials in order to do this. Bellcliffe Engineering provides a world wide service.

Our machinery and components are made to measure for each individual client; reach out to us today for exact technical specifications on our straightening rolls!

Applications

Bellcliffe Engineering cater for all sectors, including, but not limited to:

Got A Question? Get In Touch

FAQs

There are several ways of straightening tubing. The two most common forms of straightening are bend straightening and pressure straightening.

Rotary tube straightening refers to where a tube passes through a series of rolls, whilst rotating, in order to be straightened.

Pressure Straightening - this process uses pairs of rolls, whose gap can be adjusted, to force the metal tubing or pipe into shape under high amounts of pressure until it is perfectly straight. There are three different types of pressure straightening: cold bending, hot bending and impact straightening.

Bend Straightening - again, this process uses pairs of rolls to straighten out improperly constructed tubes or pipes, however, unlike pressure straightening, bend straightening forces the tube along a bending path under pressure. This pushes the material past its yield and allows spring back, which encourages straightness.