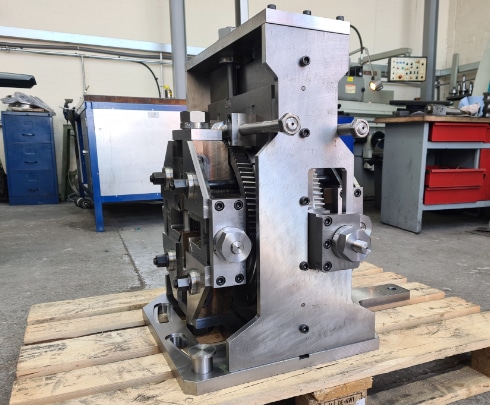

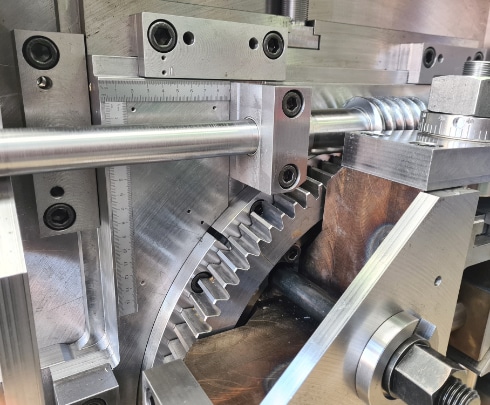

Rolling mill stands support the shafts on which the rolls are carried, rotated, and adjusted, through the use of bearings. The size and shape of stands will depend on the type of rolling process, for instance, during the initial stages of rolling, roughing stands take steel from large coils and shape it to a specific thickness. This is then followed by one or more finishing stands, which further shape the product to its final desired size and shape. Increasing the amount of stands used along a rolling mill line can increase its capability and length, as it adds more components to work the metal, and can handle higher metal strengths.

Stand refurbishment with Bellcliffe Engineering will start with a consultation, where we will discuss your problems and requirements, and assess your machinery. This guarantees your stands will be made compatible with your machinery and operation requirements, assuring total peace of mind for our customers.

Capabilities & Technical Specifications

With our refurbishment services, Bellcliffe Engineering works in collaboration with our customers to reduce the downtime of their machinery and further facilitate increased efficiency. This can generate a longer lifespan of your machine, reduced delivery times, and minimal wastage.

Refurbishing individual rolling mill stands, or alternatively undergoing a full refurbishment, will contribute to the smooth operation of your rolling line and increased output. Bellcliffe Engineering, with over 100 combined years of experience, offer full refurbishment services, repair or replacement of individual components, and fitting services for this; we moreover offer preventative maintenance services.

Our stands are made to measure for your machinery and operations, therefore for exact technical specifications, it is best to contact Bellcliffe Engineering.

Applications

Many sectors benefit from roll forming products and machinery services, and Bellcliffe Engineering can deliver for the following, as well as many more...

FAQs

The type of stand pertains to the type of rolling mill; for instance, two, three, and four high rolling mills will use stands that respectively bear two, three, or four rolls in the specific configurations.

Other configurations include cluster mill stands, which house two work rolls and a further four or more backup rolls; planetary stands, which house two backup rolls and several planetary rolls; and a universal mill stand, which house two vertical and two horizontal rolls.

There are, of course, many other types of rolling mill stands and configurations.