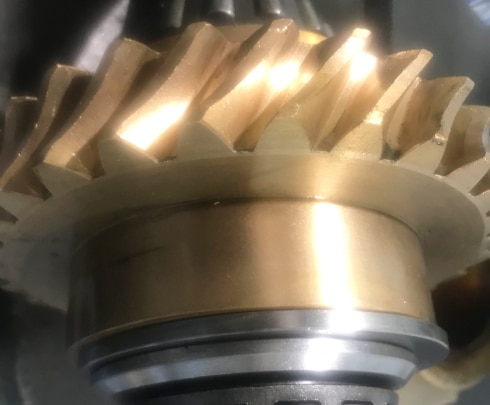

Gearboxes are mechanical devices designed to transfer rotating or linear force from one place to another. The simplest components of a gearbox are the gears themselves, which take rotational force and deliver it as torque; the geometry and tooth number of the gears determine how much torque they deliver. Though gearboxes can be simplified in this way, they can be a complex and core piece of your rolling mill, and maintaining your gearbox is essential.

Most rolling mills use gearboxes for the roller drive, and can often face high temperatures, increased loads, and long hours of operation. For this reason, gearboxes should be designed depending on the type of rolling operation, such as hot or cold rolling, and can likewise be optimised through refurbishment to encourage the efficiency of your processes.

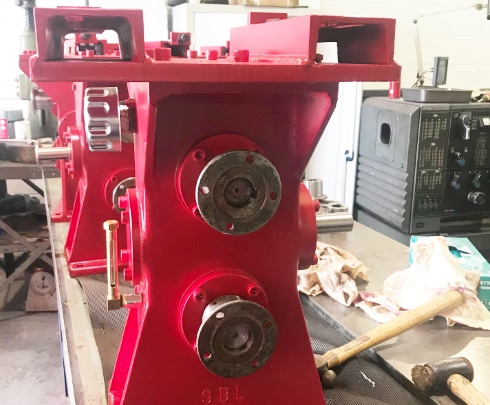

As part of our refurbishment service, Bellcliffe Engineering will carry out a consultation to assess the issues you face, and further discuss these with you. We provide a thorough and comprehensive assessment of your machinery for your peace of mind.

Capabilities & Technical Specifications

Bellcliffe Engineering works closely with our customers to help minimise their machine downtime. Minimising downtime will greatly improve the efficiency of your rolling line, leading to less scrap, shorter delivery times, and an overall longer lifespan of your machinery.

With over 100 combined years of experience, delivering to clients globally, you can trust our recommendations, formed only after a survey of your machinery. Whether you need a full refurbishment, repair of parts, and fitting services for this, or a preventative maintenance service, Bellcliffe Engineering can help you.

Our refurbishment services are bespoke to your requirements; for more information on technical specifications, reach out to Bellcliffe Engineering.

Applications

Bellcliffe Engineering can proudly provide services for the following sectors....

...as well as many more!

FAQs

During a gearbox refurbishment, the gearbox will be taken apart and components examined for wear and tear. The components must be clean in order to accurately determine the quality of the parts, and whether they need refurbishment or replacement. If components are being replaced, they should replicate the working measurements of the gearbox, unless a more adequate modification is possible. In which case, the component will undergo thorough testing to ensure it works as expected.

The gearbox itself must be cleaned alongside the components before refitting, in order to remove any debris which may inhibit the working of the gearbox, or even cause hazards. Once all the components have been refitted according to measurements and required ratios, and sealed where necessary, the gear box can be filled with oil ready for testing. During testing, the gearbox should be run for a couple hours, during which time it must be closely monitored for any problems, and slowly lubricated.