What is Roll Forming?

Roll forming is a process in which manufacturers will shape the metal using rollers to bend metal sheets or shapes. Achieving the desired shape of metal in one process is often not possible, so the sheet of metal will pass through the set of rollers until it has been correctly shaped into the desired result. This process isn’t typically used for smaller and more complex designs, but for larger and simpler shapes that can be achieved by bending sheets of metal.

Roll forming has multiple benefits, including:

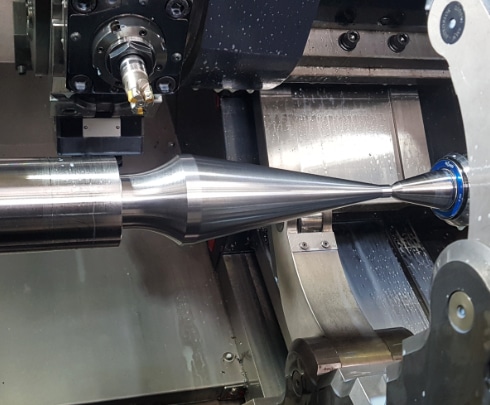

What is Extrusion?

Not all materials are capable of bending into different shapes, and some metals are much more brittle. On top of that, there are many designs that require a more complex shape - which is where extrusion comes in handy. The metal is forced through a die in the desired shape, and the metal will take the shape once it has been extruded.

Extrusion isn’t just something used on metals, and it is applicable to other harder materials like plastic and concrete.

Here are some of the benefits of extrusion:

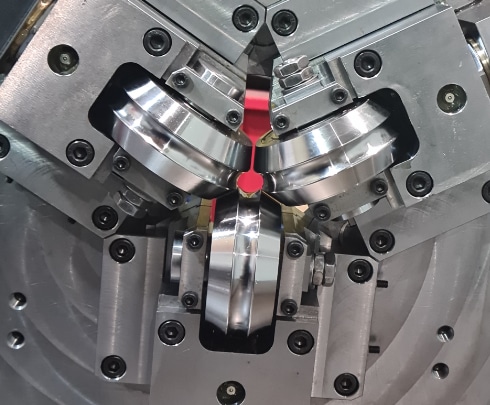

What is Press Brake?

Metal forming often requires heavy-duty machinery such as the press brake. It’s a piece of heavy-duty machinery that presses or punches the metal into the desired shape using the punch and a die. The sheet metal is placed on top of the die block and is then punched by the press brake into the shape - forcing the sheet metal to take on the shape of the die that is used. Other metal forming methods don’t typically have enough force to shape harder metals, which is where press braking would be used.

Press braking is best used for:

What is Stamping?

Metal stamping is commonly used to change sheet metal into more complex shapes. The metal is processed through a stamping press, where it is punched, stamped, and bent into its new shape. The stamping tool is designed according to match a specific shape to achieve the most accurate design once the metal has been stamped. These shapes are designed with CAD engineering technology to ensure precision when mass-producing processed metal.

Choosing A Metal Forming Technique

If you’re looking for a metal forming technique for your business, you should consider a number of factors before deciding. Some metal forming methods, like press braking can be quite costly, and not necessarily great for mass production. Simpler designs with tougher metals might be best left to roll forming. What kind of budget are you looking at, and how long are you looking to use it? Which rolling mill machine is the best for your project?

With decades of experience, Bellcliffe Engineering specialised in metal forming and the production of roll-forming mills for metal sheets and tubes. If you need help deciding the best forming process for your project, our skilled team will gladly give you advice and assist you in selecting the right method based on your project specifications and budget.

Read more ...