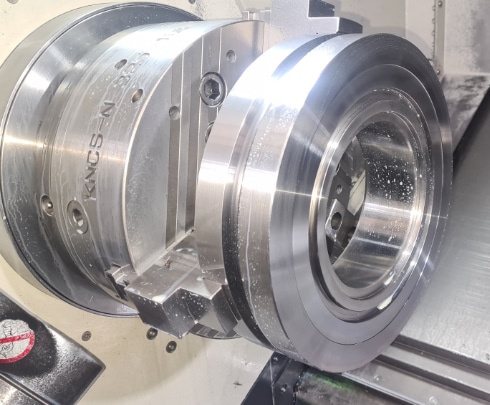

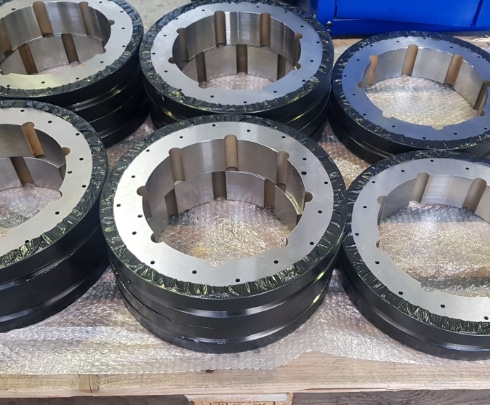

Continuous extrusion wheels can be found at the start of the extrusion line, where the material is fed onto a groove in the wheel’s circumference. This continuously rotates, guiding the feedstock into the fixed abutment and die. The wheel’s constant rotating means is crucial to creating pressure where the feedstock is blocked by the abutment, as more feedstock is pushed into the abutment. The friction of the rotating wheel against the blocked feedstock, and pressure as more feedstock enters the abutment, creates the heat necessary for making the metal malleable. It is then forced through the die to create the desired shape.

Bellcliffe Engineering have decades of experience working in manufacturing, and have the design capabilities needed to resolve your continuous rotary extrusion component issues. Whether you’re looking for a single part, or an array of components for CRE, Bellcliffe Engineering will work with you to supply them.

Capabilities & Technical Specifications

Bellcliffe Engineering meets Industry Standards when designing and manufacturing your extrusion components. Our components are designed to meet all your requirements - our customers can choose materials and heat treatments to ensure their components are suitable for their operations. We use a Hexagon Absolute Arm, accurate to within ± 9 Microns, and work with CAD and CAM software, to guarantee your components are made to measure for your business.

Bellcliffe Engineering have over 100 combined years of experience, and can deliver our services world wide.

Because our extrusion wheels are built to your exact specifications, speak to a member of our team for more information on technical specifications.

Applications

Bellcliffe Engineering provides components for aluminium and copper continuous rotary extrusion, which can be used for a number of sectors, including...

FAQs

Continuous rotary extrusion is capable of producing great lengths of finished product, which can then be cut to size; this increases the capacity for accurate replication across products and decreases the amount of wastage.

It’s also highly versatile, creating an assortment of shapes and profiles, from feedstock; the end product can be bigger than the original feedstock, since it builds up within the extrusion process and takes on the form of the die, which can be of any desired shape.

Got A Question? Get In Touch