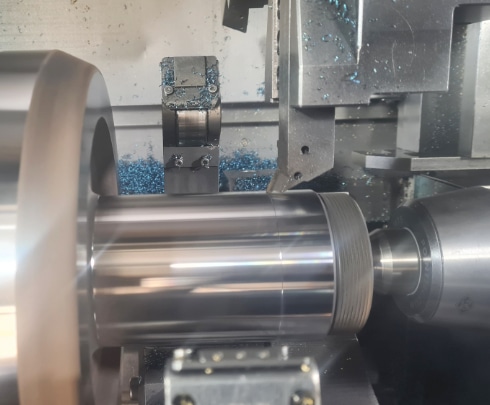

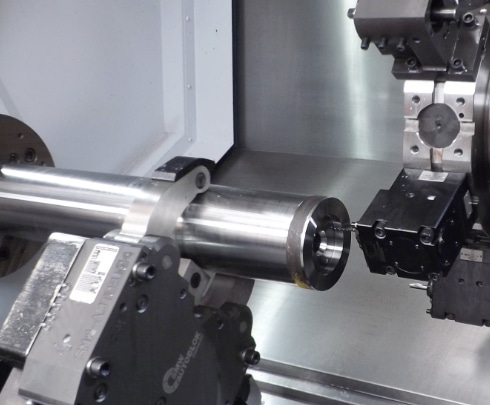

The main difference between CNC turning and other cutting methods such as milling, drilling, grinding, is that it uses a lathe instead of a drill press. In CNC turning, the part is repeatedly rotated while the tool stays in a fixed position, decreasing the diameter of the material. Tools of various sizes and shapes can be used to cut the workpiece as it is turned, depending on the desired outcome. This is all aided by a computer, which has been programmed to direct the machinery in its turning operations, guaranteeing accuracy, repeatability, and precision every time.

Bellcliffe Engineering’s experienced and specialist machinists can be trusted to design and deliver state-of-the-art machining which fulfills all your requirements.

Capabilities & Technical Specifications

To create the most accurate and functional workpieces for your operations, Bellcliffe Engineering uses a Hexagon Absolute Arm for inspection and measurements. The absolute arm is accurate to within ± 9 Microns. We use CAD/CAM software to draw and create Numerical Control programming to ensure machining is carried out to the highest quality.

We have over 100 combined years of experience within the manufacturing field, and can guide you through solutions to all your machining problems. We work with a range of materials, to ensure your machinery and components are suitable for your applications, without compromising on quality. We can deliver these services globally.

We use a Doosan Puma 3100L 2-axis lathe and 2x Nakamura ST4 2-axis lathes for our turning operations; these are 500mm D x 1.2m L.

Bellcliffe Engineering also offers

Applications

For a variety of sectors, including, but not restricted to:

FAQs

CNC turning is used to reduce the diameter of a workpiece by cutting the material as it rotates. Turning can be used for both finishing a product - leaving the workpiece with a smooth surface - or for a speedy way of efficiently reducing the size of a workpiece.

Turning can also be used for simply shaping a workpiece, adjusting the depth or angle of the turning tool as the workpiece is fed past the tooling. This can produce abrupt steps, tapered slopes, and even smooth contouring, in the workpiece.