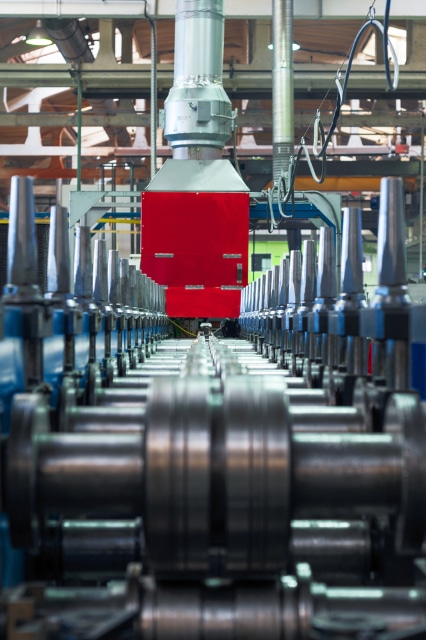

Cold Rolling Process

The steel industry heavily relies on cold rolling. The cold rolling process involves passing the desired sheet of metal between rollers. (Read more about different types of rolling mills and how to choose the rolling mill machine)

Should the desired result be a sheet or harder and firmer metal, flat rolling is used. For rods or bars of metal, profile rolling is the correct method.

The beginning of the process involves hot rolling the metal, whereby the temperature of the rollers reaches 900 degrees Celcius or more.

The metal will then be processed into cold rolling, which involves letting the metal cool down to room temperature before pickling the metal. Pickling the metal involves removing the scale that is leftover from hot rolling. The scale will interfere with the process.

Thereafter, the metal is sent through rollers that are lower than the recrystallisation temperature. This helps to relieve stress from the metal. As a result, the metal will be stronger and harder.

Each cold rolling process will reduce the metal anywhere between 50 and 90 per cent. Plus, it will increase dimensional accuracy by up to 20 per cent.

The Advantages of Cold Rolling

The benefits of cold rolled steel are:

Increased Strength

The main advantage of cold rolling includes increasing the strength of the metal. Cold-rolled steel is always much stronger than hot-rolled steel. The rollers compress the steel at room temperature, which results in more durable metal.

Improved Surface Finish

Improving the surface finish of the metal is also another benefit. The smoother surface has fewer imperfections, which will benefit the work of any business in the steel industry.

Tighter Tolerances

Cold-rolling also results in higher tolerance, which results in more durable metal. Hence, it can tolerate more stress when being used for projects.

Multiple Options

Cold-rolling steel can result in various dimensions. Hence, it offers more options and versatility than hot-rolled steel. It can be used for multiple projects including aerospace structures, home appliances, metal furniture, and mechanical components.

The Disadvantages of Cold Rolling

Cold-rolled steel can have a few disadvantages.

Nonetheless, there are fewer disadvantages and more benefits of cold-rolled steel.

Cold Rolling And Hot Rolling Difference

To summarize, the main cold rolling and hot rolling differences are that cold-rolled steel results in a much higher strength product. There is less internal stress in cold-rolled steel too, which makes it more durable and resistant – making it ideal for use across multiple industries.

Read more ...