What is EDM Spark Erosion Used For?

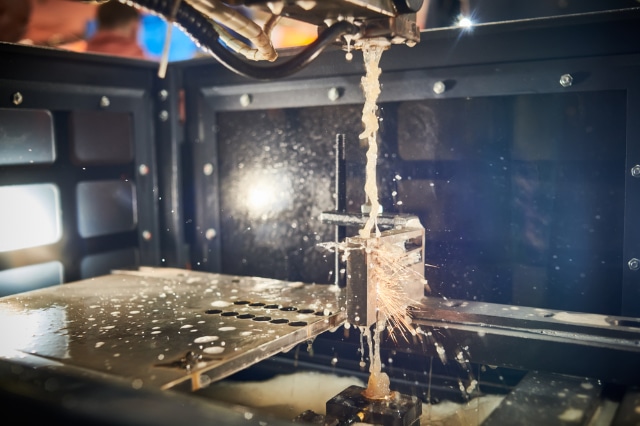

EDM spark erosion is a form of electro-erosion machining that uses electrical sparks to cut or shape materials. The process works by generating an electrical pulse between the material and the electrode, which helps to wear away the metal from both sides. This makes it ideal for intricate shapes and parts with tight tolerances. EDM spark erosion is used in many industrial applications, such as die manufacturing, tool making, and prototyping.

In manufacturing, EDM spark erosion can be used to create complex shapes and cavities in hard materials such as steel, tungsten carbide or titanium alloys. The process is also well-suited for producing small parts with tight tolerances, including micro parts like those found in various electronics applications. In addition, it is highly accurate and repeatable, making it an ideal solution for specialised production needs.

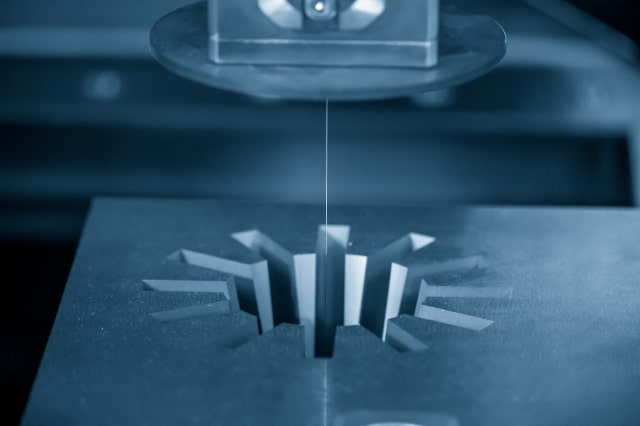

For tool making, EDM spark erosion allows manufacturers to create high-precision tools quickly and with minimal material waste. This makes it an efficient solution for creating complex cutting tools, such as threading dies or punches. The process can also be used for hard milling, where the electrode is moved along a predefined path to cut intricate shapes into metal surfaces.

And for prototyping, EDM spark erosion is an excellent choice for creating complex parts with small tolerances. By specifying the desired shape and size of a prototype, the electrode can be used to cut and craft the exact part needed. This makes it ideal for applications where precise measurements are required, or modifications need to be made quickly.

What are EDM Electrodes?

EDM electrodes are an essential part of the EDM spark erosion process. EDM electrodes are materials or tools used to direct the electrical pulses during spark erosion. The material of the electrode is chosen based on its ability to withstand the high temperatures generated during the process and its ability to conduct electricity.

These electrode materials can be made from various metals, such as copper, tungsten, aluminium and graphite. Each electrode material has distinct properties that make it well-suited for specific applications.

Copper electrodes are often preferred when high accuracy and fine detail are required. They can be used for deep hole drilling, contouring and profiling applications, as well as hard milling and prototyping. Copper electrodes also have a long life span and offer excellent electrical conductivity.

Tungsten electrodes are highly durable with excellent abrasion resistance, making them ideal for high-speed cutting operations or repetitive machining processes. Tungsten electrodes can also be used to produce intricate shapes with tight tolerances, although they may require longer cutting times than copper or aluminium counterparts.

Aluminium electrodes provide good electrical conductivity and low thermal expansion properties, making them suitable for light machining operations such as trimming and contouring. They are also extremely resistant to heat, making them an excellent choice for high-temperature applications.

Graphite electrodes are typically used for EDM spark erosion operations that require very low currents and slow machining speeds. Graphite electrodes have excellent wear resistance and offer superior surface finish quality when compared to other materials. Additionally, graphite can be tailored to meet the specific needs of each application by varying its composition.

What are Spark Electrodes Made of?

Spark plugs are made up of several components that must be precisely machined in order to ensure efficient operation and long-term reliability. These components include the shell or body, the insulator, the centre electrode and the side or ground electrode.

The shell or body is typically made from steel, aluminium or brass and is formed by a cold-heading process. This creates a preformed shape that requires minimal post-processing before assembly. The electrodes themselves are usually copper or graphite, as these materials have excellent electrical conductivity and can withstand extreme temperatures.

The insulator is made from a ceramic material such as aluminium oxide or steatite and is used to keep the electrical charge from arcing between the electrodes. The spark gap is machined into the insulator and filled with a non-conductive material such as mica, which helps conduct the electrical current more efficiently.

The centre electrode is typically made from copper or nickel-iron alloy, such as stainless steel wire, that has been drawn to a very fine diameter. This increases surface contact between the electrodes, resulting in improved ignition performance.

The side electrode or ground electrode is typically made from a harder material, such as graphite or steel, that can withstand the intense heat produced when firing the spark plug.

Which EDM Electrode is Superior, Graphite or Copper?

The answer to this question depends on the application. Both graphite and copper EDM electrodes possess unique properties that make them best suited for different operations.

Graphite

Copper

Ultimately, the choice of which EDM electrode material is superior will depend on the application and its specific needs. Bellcliffe Engineering offers a wide range of spark erosion electrodes that are tailored to meet any requirement, so contact us today to discuss how we can help with your project.

Bellcliffe Engineering, with over four decades of milling and machining experience, is well-versed in wire and spark erosion. Our knowledgeable team will gladly assist you with your projects. For more information please contact us.

Rad more ...